Hyundai Motor, Ulsan, Korea

Installation Details

Location: A car engine manufacturing factory, Hyundai Motor Ulsan

Area: A cold water circulation pipeline for the cooling tower and the induction hardening machine

Pipe size: 100 mm

Model: Vulcan S25

Installer: Vulcan-Korea team

- Scale problems in the pipelines and the induction hardening machine.

- There are 9 secondary small pipes, they had to be cleaned manually every 2-3 months

Installation of a Vulcan S25 unit:

May 21st, 2018.

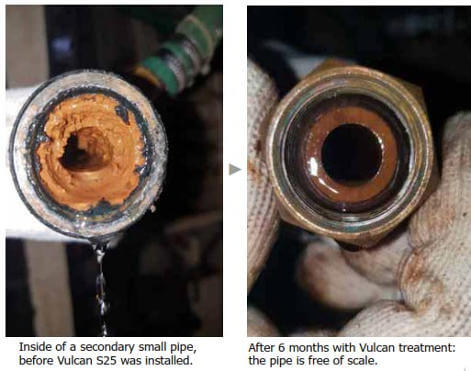

Note: scale was not manually removed before the Vulcan was fitted on source pipe (see photo).

Examination of secondary piping:

November 21st, 2018

- Since Vulcan S25 was installed, the Hyundai Engineering Team has stopped the regular manual cleaning process.

Observation: the flow rate with the Vulcan unit is now even higher than immediately after previous manual cleaning had been done. - After Vulcan S25 had been installed for 6 months, the secondary pipes were opened: scale that had been left in piping had disappeared and all 9 secondary pipes had become clean (see photo).

Observation: Biofilms in the cooling tower had disappeared since the Vulcan unit was installed.

Vulcan S25 was installed around 50 meter before the induction hardening machine.

There are 9 secondary small pipes with water meters. These meters were installed to make sure a stable flow rate. If the flow rate goes down, it would cause a problem of the induction hardening machine. Therefore, the pipes had to be cleaned manually every 2-3 months.